Discharge Heads of The vertical mixed flow turbine pumps

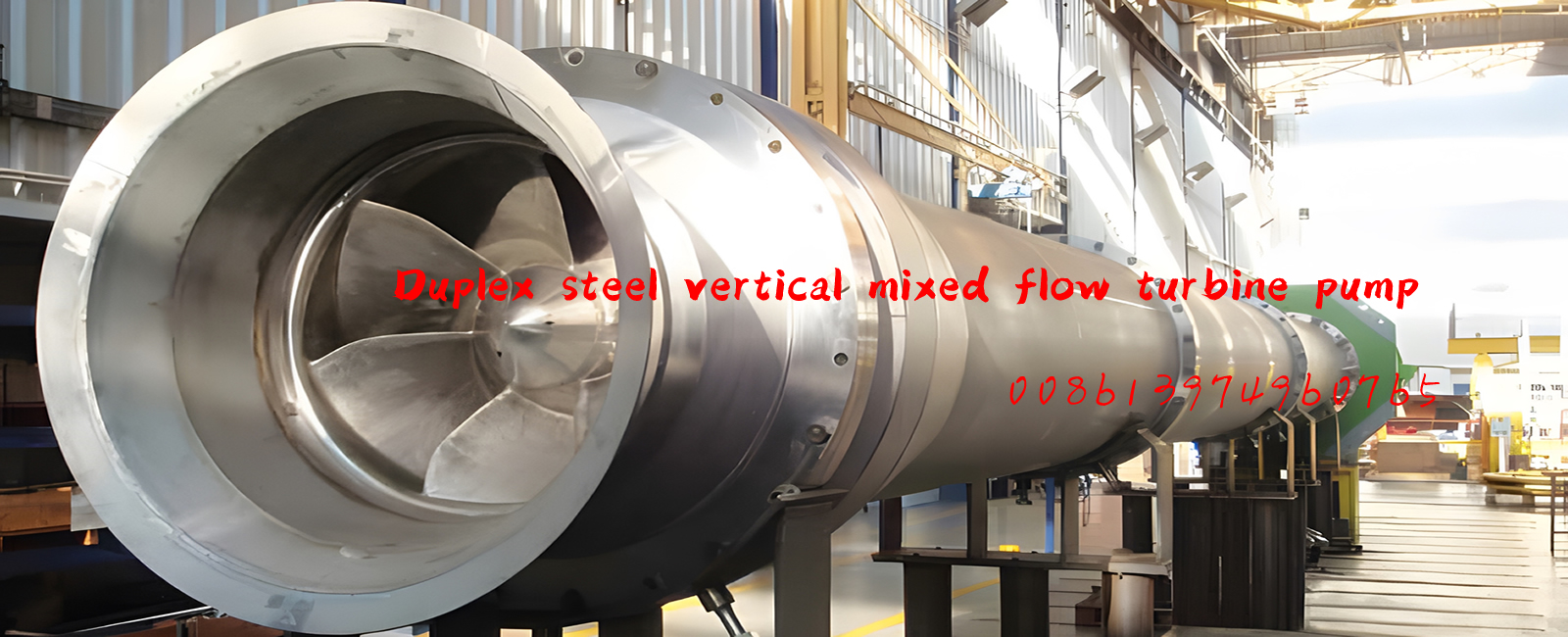

Structural versions: Fabricated steel type “A” and “B” with discharge elbow, fabricated steel type “C” and cast iron type “D”. The weight of column pipes and vertical mixed flow turbine pump is carried by the baseplate of the discharge head. Driver mounting flange machined to NEMA standards to accept any vertical drive arrangement.

The standard discharge head is the type “A”. The elbow for type “A” is integral with the baseplate and can be either above (ABE) or below (BBE) it, depending on the installation requirements. Elbow below base is usually preferred as its lower centre of gravity makes for more stable vertical mixed flow turbine pump and motor. Normally the elbow discharge is horizontal ( at 90 degrees to the vertical mixed flow turbine pump shaft), but other angles can also be supplied when required . The elbows are made from standard steel pipes, electrically welded. The standard elbow is made with one

45 degree section. Long sweep elbows with five intermediate sections can also be supplied.

Head-Shaft : Standard two – piece head-shaft arrangement with head-shaft coupling immediately above stuffing box. Head-shaft is made of stainless or carbon steel with sleeve of stainless steel at stuffing box position.

Stuffing box: The water and grease lubricated vertical mixed flow turbine pumps are furnished with a packed stuffing box. Bronze split gland can be completely removed from the vertical mixed flow turbine pump for easy packing replacement without disassembly. Mechanical seal is available upon request.

In oil lubricated vertical mixed flow turbine pumps, the leakage between tension nut body and tube protective sleeve is positively prevented by O-ring seal.

QQ

QQ